Production Tracking System

Instant tracking, quality and optimization are under control in production

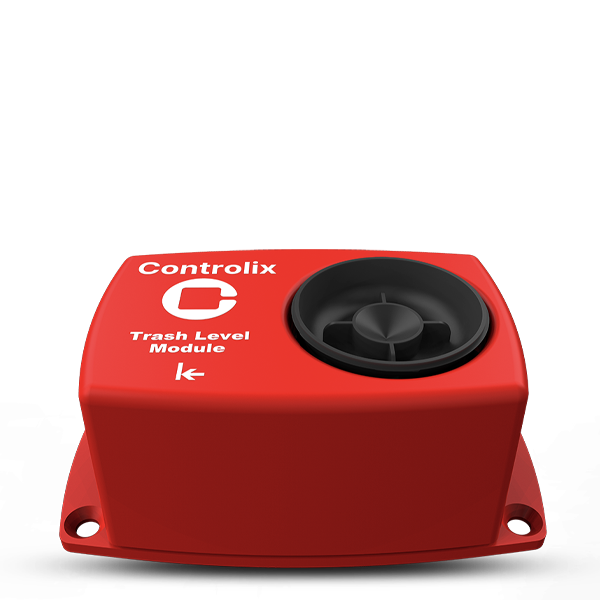

Controlix

Production Tracking System

We begin the processes of digital transformation of factories, thanks to our solutions that optimize quality and production costs by monitoring the production lines as closely as possible.

Why Production Tracking System?

The production tracking system, which is the main starting point of Industry 4.0 transformation, provides instant production tracking, quality and optimization. We are talking about a transformation where production costs, especially facility resource costs, can be compared and a benefit model analysis can be performed. Data acquisition solutions form the basis of these solutions, which are closely linked to all production line owners. Transforming data received from analog or digital lines into a meaningful form and producing forward-looking reports constitute the whole production tracking system. To that purpose, as a team of Controlix engineers, we produce sensors and software solutions that easily integrate into all existing production lines in the industry. Thanks to our solutions capable of easily collecting all the necessary data, in particular with the Mes Integrations solution, the production lines are monitored instantly.

Controlix Production Tracking System Solution can transfer the database to all existing MES software.

Controlix Production Tracking Systems, which we present with mainly obtained data such as production data to be obtained in our solution, stop signal, quantity information, periods, work order information, information onmachine maintenance and waste information;

• Production Line Planning,

• Oee Productivity Analysis,

• Operation Analysis,

• Speed Tracking and Analysis,

• Predictive Maintenance Process,

• Information on Wasted Production Time,

• Instant Monitoring of All Resources (Water, Gas, Electricity),

• Energy Analysis and Efficiency Monitoring,

• Work Order on Hmi Screens,

• Optimization with Data Peripheral Equipment,

• Failure Response Time,

• Instant Tracking Solutions, (Mobile App, Alarm and Web Platform)

•Loss Analysis,

• Andon App

We begin the processes of digital transformation of factories, thanks to our solutions that optimize quality and production costs by monitoring the production lines as closely as possible. Profit and loss analyzes can be easily calculated thanks to the solutions where cost elements of manufactured products can be seen instantly and loss costs caused by downtime can be easily calculated. As we can deliver our solutions from our own platform, we can also transfer data directly to existing MES integrations. we can integrate the data we can get from old analog machines into the database of existing MES applications. With the data obtained, various algorithms and reporting processes can be easily applied.

From field login to authorization, it has strong layers of security.

Although it can collect and store lots of data in different data sources, it also has lots of reporting modules.

The Controlix Platform is an intelligent system developed by Kontrolmatik engineers, which can collect and store a lot of data in different data sources, perform real-time analytical calculations and also unattended actions with numerous reporting modules.

The Controlix platform, which has remote access with cloud technology, allows you to use it without any server and security investment.

Important Solution Benefits

Controlix Platform

The Controlix Platform is an intelligent system developed by Kontrolmatik engineers which can collect and store a lot of data in different data sources, perform real-time analytical calculations and also unattended actions.